Capabilities

Health and Safety

Maintaining a safe work environment is not an add-on or a premium, but rather a natural extension of a quality plan that’s well executed. Each Arc team member is responsible for consistently following all established safety procedures, and for fostering a proactive culture focused on safety.

Led by our Senior Environmental Health and Safety Manager, Danielle Zientek, we work to empower staff, subcontractors, clients and designers to learn, discover and work in a manner that protects human health and the environment.

Additionally, Dani brings decades of experience managing projects with environmental issues ranging from building components with lead and asbestos, to soil and groundwater contamination. Whatever environmental challenges arise, Arc team members have the added value of carrying forward these successful collaborative relationships to ensure a project’s success.

Lean Construction

Our Lean Construction approach relies on Target Value Design to maximize the output and efficiency of a project while minimizing waste and time delay. Our Vice President of Field Operations, Dwayne Fleming, leads our on-site pull-planning efforts, wherein team members and subcontractors work together to plan the outcomes needed for a project. Through this process, workflow becomes more reliable and efficient as the waste of waiting, redundancy and over-processing are eliminated. This up-front collaboration is critical for allowing the team to identify and eliminate potential conflicts at the outset, making for a smoother, more cost-effective construction process.

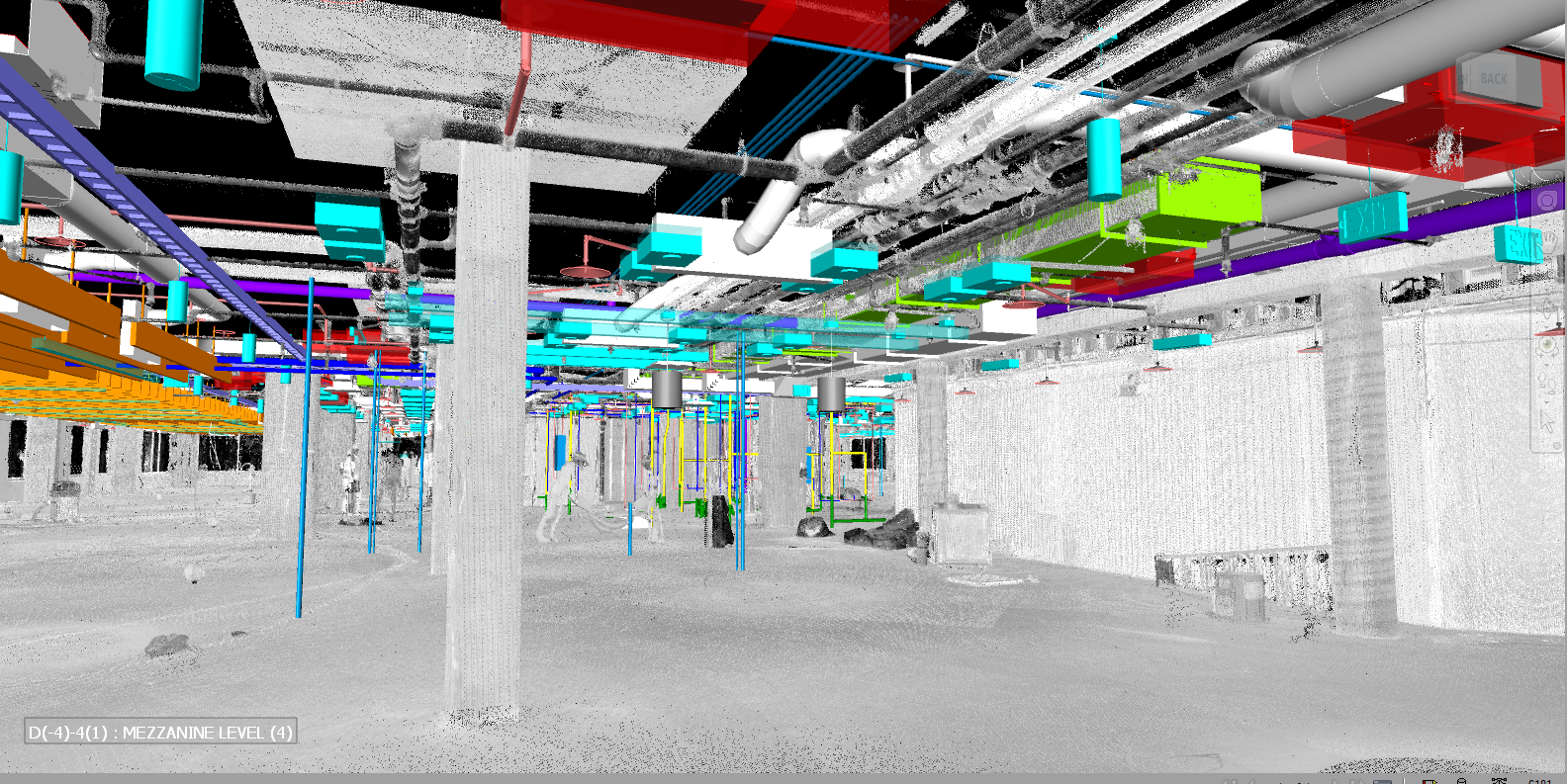

CannonDesign Headquarters

The headquarters project is a renovation of the 2nd floor of an existing office building in downtown Buffalo. Demolition was completed to allow for the new space. Once demolition was completed, a scan was performed to capture all services on the floor. This scan was then provided to the subcontractors and used in coordinating Mechanical, Electrical and Fire Protection trades with existing conditions. The scan also provided a 'heat map' of the floor flatness/levelness. Any clashes were identified and corrected.

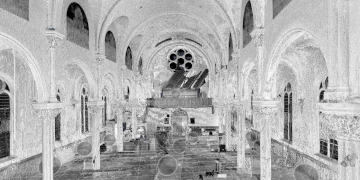

St Lucy's Church

St Lucy’s Church is a site with 3 existing buildings. The church is a historical landmark, with the exterior façade being preserved and incorporated into the new mixed-use building that will be going on this site. The design is set to preserve the exterior 20 feet of the 3 existing structures. A scan was completed to capture the existing 20 feet as well as the crawl space under the church to have a better understanding of what structure they needed to support, as well as work around for the new building. The owners also wanted to document the existing structure on the exterior façade for historical record. With the level of detail needed on the exterior, a color high-resolution scan was done to capture the detail. While the interior was done in black and white to capture the information, the colors were not necessary. Once the scan was complete, a model was created at a level 300-400 detail to capture all the custom brick work on the church, as well as the archways and corbeling on the rectory and shelter.

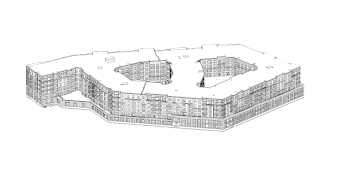

Bayonne Avenue G

Expected to reach a completed size of 656,120 sq. ft. in 2024, this $89 million mixed-use residential building is designed to be 6 stories high with 354 apartments. Our team utilized VDC to coordinate the MEP elements of the project, allowing us to identify and resolve any conflicts during the design phase. Coordination meetings prior to construction create a collaborative environment for conflicts to be discussed, ultimately helping the project team achieve the most optimal outcomes. The 3D model of Bayonne Avenue G is hosted and published in Procore, ensuring that any advanced conflicts can be directly escalated to the design team all within one platform.